Stainless steel pipe pickling line

The advantages and development trend of automated pickling treatment

Automated pickling surface treatment equipment has advantages that traditional pickling methods and other acid-free treatment methods can’t compare:

★ Good surface quality—— the medium used is still acid, so the surface quality still retains the advantages of traditional pickling

★ Automatic production—— continuous automatic production, high production efficiency, large output, various process parameters are controlled by a computer, production has been automatically. The process is stable, especially suitable for large-volume, centralized production

★ Low production cost—— automatic control of process parameters, the production process can be optimized, with reasonable and effective production media circulation. Ring utilization, while automated production can effectively reduce personnel costs. These factors make the automated pickling equipment. The operating cost of equipment is much lower than that of traditional pickling

★ Low environmental pollution—— the automated pickling equipment can be equipped with advanced waste water and waste gas treatment devices, combined with the characteristics of its own equipment,Achieve relatively low emissions and minimal pollution to the plant and its surroundings. Especially for acid mist treatment and water treatment. On the other hand, if equipped with suitable acid regeneration and wastewater treatment equipment, zero emissions can even be achieved.

With the advancement of technology, automated pickling equipment will gradually realize seamless connection with logistics tracking, MES, ERP and other systems. With industry 4.0, machine vision, cloud big data and other technologies, can achieve a higher degree of intensive, automated, and multi-variety production, bringing huge economic benefits to the enterprise.

Typical process configuration

Features

★ Advanced and reliable manipulator

• Specially designed special electric lifting device, suitable for the continuous operation of this type of production line;

• Using 4-motor drive device, synchronous operation, quick start and reliable braking;

• The robotic arm adopts a multi-guiding structure, which runs smoothly and with low noise;

• The movable pulley frame adopts a 2×3 structure with 3 guide wheel mechanisms to ensure that the manipulator rises and falls smoothly without shaking;

• Equipped with multiple safety detection sensors to ensure the safe operation of the manipulator and protect the personal safety of personnel;

• Specially optimized mechanical structure, long service life of parts, easy maintenance and repair, and quick replacement of parts.

★ Compact layout, factory production of steel structure, high-strength bolt connection

• Easy to maintain and save maintenance investment;

• Stronger than traditional welding, completely eliminate the influence of steel structure stress;

• The equipment is elegant in appearance, easy to install and short in construction period.

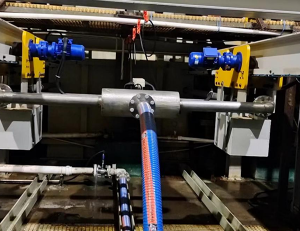

★ Pickling adopts external circulation technology

• There is no heat exchange element in the pickling tank, which is convenient for cleaning and maintenance;

• External circulation filtration technology keeps the tank clean and can quickly clean up the residue in the acid solution;

• Dynamic turbulent pickling improves pickling effect and pickling efficiency.

★ High-efficiency water circulation and water-saving cleaning design

• Invention patent technology;

• Reverse cascade water circulation cleaning;

• High flow rate and swing cleaning can clean the steel pipe surface more effectively;

• Realize dynamic rinsing and improve cleaning effect;

• Less water consumption means lower waste water discharge, improving user economic benefits.

★ Advanced and convenient control system and reliable program design

• Multiple positioning of photoelectric sensor, proximity switch and positioning sensor, combined with software algorithm, to prevent collision accidents;

• High positioning accuracy, positioning error ≤ 5mm;

• What you see is what you get: The display status and position on the HMI are exactly the same as the status of the field equipment, which is convenient for the operator to understand the operation status of the equipment;

• Strict safety control and safety sensor configuration to avoid personal accidents and ensure personnel safety;

• When feeding, the operator can click on the material loading HMI according to the type of material to automatically match the corresponding production process;

• Technicians can modify and add process procedures to better adapt to the processing of multiple types of products;

• Advanced multi-point WIFI AP function to ensure that the WIFI signal has no dead ends and ensure the normal operation of the device;

• Internet of things interface, cloud platform control, mobile phone and tablet can be remotely online (option);

• The MES system interface is reserved, and the MES system can be seamlessly connected with this equipment, which is convenient for production management.